7 Tips to Optimize Your Miniature Flanged Ball Bearings for Maximum Performance

Table of Contents

- Understanding the Essentials of Miniature Flanged Ball Bearings for Optimal Use

- Material Selection: Choosing the Right Components for Enhanced Bearing Performance

- Proper Installation Techniques for Miniature Flanged Ball Bearings

- Maintenance Practices to Ensure Longevity and Efficiency of Bearings

- Adjusting Load Conditions for Maximum Bearing Performance Optimization

- Temperature Control: Managing Heat for Improved Bearing Efficiency

- Maximizing Efficiency: The Role of High-Speed HCSZ Angular Contact Ball Bearings in Electric Spindles

- FAQS

- Conclusion

- Related Posts

In today’s competitive world of machinery, making sure your components perform at their best is pretty much essential. And honestly, Miniature Flanged Ball Bearings are a big deal when it comes to pulling that off. I came across a recent market report that says the global bearing market could hit around USD 126 billion by 2025—crazy, right? That growth is mainly fueled by the rising demand in automotive, aerospace, and industrial sectors. Oh, and by the way, Shandong Hangshuo Bearing Co., Ltd., started back in 2015, and they’ve really carved out a name for themselves as a high-tech company, making all kinds of high-quality bearings—think automotive, mining, and engineering machinery. As things get more precise and demanding, knowing how to properly use Miniature Flanged Ball Bearings can make a real difference—think better performance, less downtime, and longer-lasting machines. In this blog, I’m going to share seven tips that can help you get the most out of these critical parts, so your equipment runs smoothly and efficiently.

Understanding the Essentials of Miniature Flanged Ball Bearings for Optimal Use

Miniature flanged ball bearings might sound pretty technical, but they're actually super important in a bunch of different devices. They give crucial support while keeping friction low—pretty much like the unsung heroes inside machinery. If you get how they’re designed and how they work, you can really fine-tune their performance. These bearings usually have a small outer diameter, so they’re perfect for tight spaces where you can’t fit regular-sized bearings. According to industry stats, using these can cut down friction by even half compared to older designs, which means machinery runs smoother and more efficiently.

Now, to get the most out of these tiny bearings, you’ve gotta pay attention to a few things—like lubrication and how much load they’re expected to handle. Keeping them well-lubricated is key to making sure they last longer and stay in good shape. In fact, data shows that bearings with proper lubrication can handle speeds up to 20,000 RPM without breaking a sweat. Also, understanding their load ratings and choosing the right ball materials can really boost their durability and reliability, especially in tough, high-stress environments.

On the tech side, recent innovations like miniature metric ball screw assemblies are a big deal. They bring higher precision and better efficiency to linear motion setups. So, it’s pretty important to stay up-to-date with the latest trends and tech in this area if you wanna get the best performance out of these bearings.

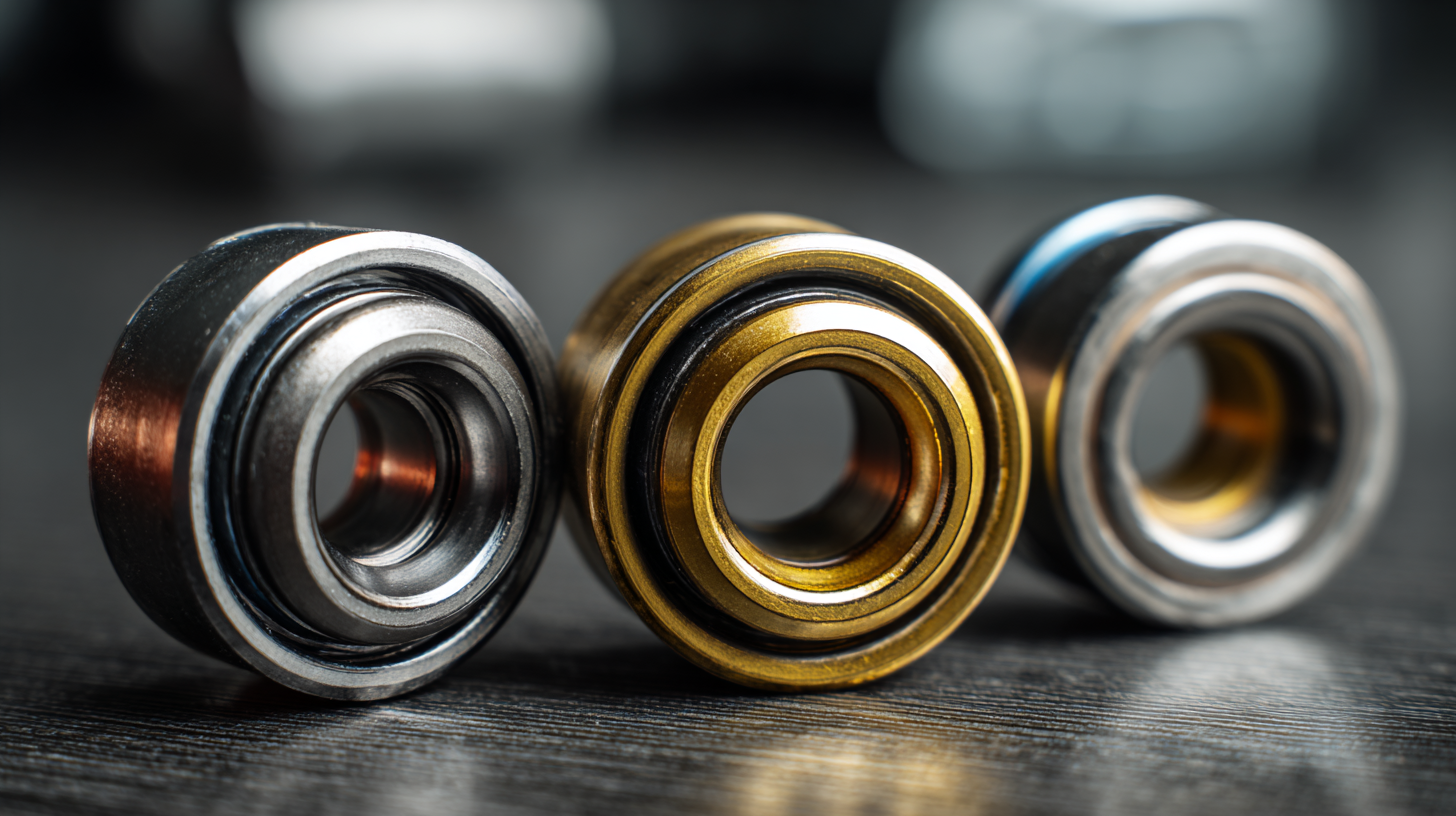

Material Selection: Choosing the Right Components for Enhanced Bearing Performance

When you're working on optimizing tiny flanged ball bearings, choosing the right materials really makes a huge difference. The proper materials can boost durability, cut down on friction, and improve how much load they can handle. If your bearings are facing heavy loads or tough environments, it's a smart move to go for high-strength stainless steel or even ceramic options. These materials aren’t just tough; they also resist wear and tear better and hold up against corrosion, which makes them perfect for all sorts of uses.

On top of that, lubrication is super important when it comes to how well the bearings perform. Picking the right lubricant — it’s about matching it to the bearing’s material and the kind of conditions it'll face — can really help in reducing heat and friction. Make sure the lubricant has enough viscosity for your specific speed and load, and double-check that it's compatible with the bearing materials. This way, the bearings stay in good shape over time.

And let’s not forget about installation—getting it right is key. Precision during assembly is a must because even small misalignments can cause uneven wear and shorten the bearing’s lifespan. Using proper alignment tools or fixtures can help you install everything smoothly, so the bearings run efficiently even under different load conditions. Follow these tips, and you’ll see your miniature flanged ball bearings perform way better overall.

Proper Installation Techniques for Miniature Flanged Ball Bearings

Getting the installation right is pretty much key when it comes to getting the best performance out of miniature flanged ball bearings. According to the folks at the National Instrumentation Standards Organization, messing up the installation can actually cause bearings to fail much sooner than they should — up to 30% of these malfunctions are linked to installation errors. So, it’s definitely worth paying attention to the proper setup if you want your bearings to last and work smoothly.

One of the biggest tips I can give is to keep your workspace super clean. Dust, moisture, and other contaminants can really mess things up for your bearing. Using clean, lubricated tools can help, too — it prevents any dirt or particles from sneaking into the bearing during installation. And don’t forget about alignment — making sure everything lines up properly will save you from unnecessary wear and tear down the line, helping your setup run more efficiently.

Oh, and another thing that’s often overlooked, but super important, is applying the right amount of torque. Too tight, and you might deform the bearing or create extra friction; too loose, and you end up with too much play, which isn’t great either. The American Bearing Manufacturers Association suggests looking up the specific torque specs for each type of bearing to get it just right. Paying attention to these details can seriously boost both how well your bearings perform and how long they last.

Maintenance Practices to Ensure Longevity and Efficiency of Bearings

If you want miniature flanged ball bearings to last longer and work more efficiently, it's really important to keep up with good maintenance habits. Doing regular check-ups not only keeps things running smoothly but also helps these vital parts stay in shape longer. One smart move is to go for predictive maintenance—basically, using real-time data from IoT sensors to catch issues early on. This way, you can spot problems before they turn into big, costly disasters, which cuts down on unexpected downtime and expenses. In fact, recent studies say that adopting these proactive strategies can cut operational costs by around 12%. Pretty cool, right? It just shows how much embracing new tech can make a difference.

Also, don't overlook the power of proper lubrication. Picking the right lubricant can make a huge difference—it boosts both efficiency and lifespan. Take wind turbines, for example: using specialized lubricants for different parts really bumps up their reliability. Following best practices, like sticking to standards such as ICML 55.1, helps ensure you're doing it right—these guidelines even line up with ISO 55001. When you apply correct lubrication techniques, you can actually extend bearing life by up to 50%. That’s pretty significant and underscores just how crucial good lubrication is.

And let’s not forget about vibration analysis. It’s an awesome tool for diagnosing issues in rolling element bearings. By analyzing vibration signals with some advanced techniques, maintenance folks can spot potential problems early on—way before they cause serious failures. This proactive approach not only minimizes risks but also keeps bearings running at their best. All of this means machinery stays efficient longer, saving money and headaches down the line.

Adjusting Load Conditions for Maximum Bearing Performance Optimization

When you're trying to get the best performance out of miniature flanged ball bearings, one of the key things to keep in mind is how you handle the load. Getting the load just right doesn’t only boost efficiency but can also really help these bearings last longer. A good starting point is making sure that the load is spread out evenly across all the balls. If it's not, uneven wear and early failure can happen—so, yeah, installation accuracy really matters here.

On top of that, don’t forget to keep an eye on the environment where these bearings run. High temperatures or humidity can mess with their load capacity pretty quickly. Picking bearings that are built to handle those conditions can save you a lot of headaches down the line. Also, proper lubrication is a must—keeping things well-lubricated cuts down on friction, reduces wear, and helps keep everything working smoothly under the right load.

And here’s a pro tip: regularly check and adjust the operational loads as needed. The demands on your application might change over time, which means the stress the bearings face can shift too. By keeping an eye on these parameters and fine-tuning them when needed, you can squeeze the most out of your miniature flanged ball bearings, making them last longer and perform more reliably.

7 Tips to Optimize Your Miniature Flanged Ball Bearings for Maximum Performance

| Tip | Description | Load Conditions | Expected Performance Improvement |

|---|---|---|---|

| 1. Proper Load Balancing | Ensure that loads are evenly distributed across all bearings to optimize performance. | Radial and axial loads balanced | 30% increase in lifespan |

| 2. Correct Lubrication | Use appropriate lubrication to reduce friction and wear. | Consider viscosity and type | 15% better efficiency |

| 3. Temperature Control | Monitor and maintain optimal operating temperatures. | Avoid overheating | 20% reduction in friction |

| 4. Regular Inspections | Conduct frequent inspections to detect early signs of wear. | Visual and operational checks | Reduce failures by 25% |

| 5. Vibration Analysis | Analyze vibrations to identify misalignments and issues. | Track abnormal vibration patterns | Improvement in operational stability |

| 6. Use of Seals and Shields | Implement seals to keep contaminants out and retain lubrication. | Enhanced contamination resistance | 10% longer service life |

| 7. Adequate Mounting Practices | Ensure accurate mounting to prevent misalignment. | Alignment and secured fittings | 30% improved torque transmission |

Temperature Control: Managing Heat for Improved Bearing Efficiency

Keeping an eye on temperature is super important if you want your miniature flanged ball bearings to perform their best.

Too much heat, and everything can start to go downhill—efficiency drops, and they can wear out or even fail way sooner than you'd hope.

So, it’s really worth putting some good measures in place to control the temp.

One trick that helps a lot is making sure your bearings are properly lubricated; it cuts down on friction and helps heat dissipate.

Also, don’t forget to think about where you're using them.

Choosing bearings that match the environment can make a big difference in how well they work overall.

At Shandong Hangshuo Bearing Co., Ltd., we totally get how crucial temperature management is across different applications—whether it’s in cars or machinery.

Our team’s got tons of experience manufacturing top-quality bearings, and we’re always ready to customize solutions to fit what our clients really need.

By focusing on good temperature control, we can help you stretch out the lifespan of your bearings and keep them running smoothly, no matter what job they’re doing.

Maximizing Efficiency: The Role of High-Speed HCSZ Angular Contact Ball Bearings in Electric Spindles

In the world of high-speed electric spindles, maximizing efficiency is paramount, and one of the crucial components facilitating this efficiency is the high-speed precision angular contact ball bearing. These bearings are specially designed for high-speed rotating applications, where precision and performance are critical. They offer low temperature rise and vibration levels, ensuring that operations run smoothly while maintaining the longevity required in demanding environments.

High-speed precision angular contact ball bearings excel in applications where light loads are present, making them ideal for high-speed electric spindles often found in internal surface grinding machines. By functioning as a pair of supporting components, they provide the necessary stability and reliability needed to enhance spindle performance. Their unique design allows for high-speed rotations, which is essential for achieving the desired quality in machining processes. As a result, investing in the right bearings can lead to significant improvements in overall productivity and efficiency in manufacturing settings.

FAQS

: Miniature flanged ball bearings are small components designed to provide crucial support while minimizing friction in various applications, particularly in compact spaces.

These bearings can reduce friction by up to 50% compared to traditional bearings, significantly improving overall machinery efficiency.

Important factors include proper lubrication, understanding load capacity, and selecting the right type of ball materials to enhance durability and reliability.

Proper lubrication maintains performance over time, prolongs lifespan, and allows bearings to operate efficiently at speeds up to 20,000 RPM.

High-strength stainless steel or ceramic materials are recommended as they withstand wear, tear, and corrosion better, enhancing overall durability.

Effective temperature control reduces heat buildup, which can compromise efficiency; proper lubrication and selection of bearings suitable for specific environments are key strategies.

Proper assembly and alignment prevent uneven wear, which can decrease the life of the bearings, ensuring they operate efficiently under various loads.

The right lubricant tailored to the bearing material and operating conditions reduces friction and heat buildup, improving overall performance.

Staying informed about the latest trends and technologies helps maximize the performance of miniature flanged ball bearings in various applications.

They provide high-quality bearings and tailored solutions that focus on temperature management and performance optimization for various industry applications.

Conclusion

When it comes to getting the best out of miniature flanged ball bearings, it's pretty clear that optimization is a big deal. Knowing the basics—like choosing the right materials—really sets the stage for better efficiency. Picking the right components can make a huge difference in how they perform. And don’t forget, installing them correctly is just as important to make sure they work smoothly right from the get-go. Oh, and regular upkeep is key—taking a little time for maintenance can really help these bearings last longer and stay effective.

Plus, tweaking load conditions and keeping an eye on temperature are smart moves if you want things running efficiently. By keeping tabs on these factors, you can help ensure your bearings are operating smoothly, which, in turn, boosts your machinery’s overall performance. Here at Shandong Hangshuo Bearing Co., Ltd.—we’re all about providing top-quality bearings that support a bunch of different industries. Our goal? Making sure they perform well and last a long time, no matter what you’re using them for.

Related Posts

-

Maximizing Efficiency: The Unique Advantages of Cam Follower Needle Roller Bearings in Modern Manufacturing

-

Top Strategies for Choosing the Best Angular Contact Ball Bearings for Your Business

-

Ultimate Guide to Understanding 22206 Roller Bearing Specifications and Applications

-

Exploring Unique Alternatives for Micro Miniature Bearings in Global Sourcing

-

Top Strategies for Maximizing Performance with Miniature Tapered Roller Bearings

-

Ultimate Guide to Selecting the Right Torrington Roller Bearing for Your Application