The Importance of Bearings in Machinery and Their Working Principle

The role of bearings in machinery is indispensable. Their primary function is to support rotating mechanical components, reduce friction coefficients during transmission, and minimise mechanical loads. In simple terms, bearings are the small components that enable machinery to rotate while maintaining stability and reducing wear and tear. Without bearings, a shaft would merely be an ordinary iron rod.

The Working Principle of Bearings

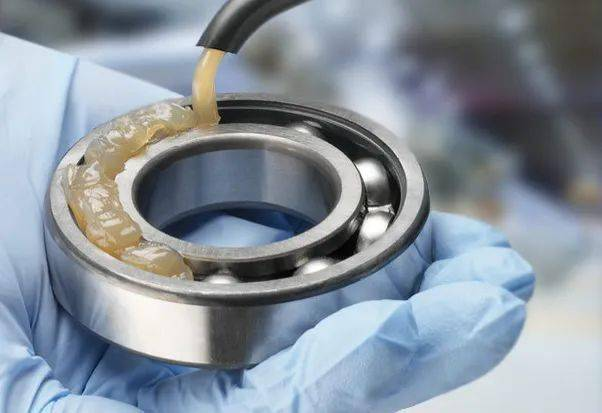

The foundation of bearings is rolling bearings, which operate by replacing sliding friction with rolling friction. Rolling bearings typically consist of two rings, a set of rolling elements, and a cage. This structure gives bearings a high degree of versatility, standardisation, and series production. Due to the varying operating conditions of different machinery, rolling bearings are subject to different requirements in terms of load capacity, structure, and performance. Therefore, rolling bearings require a variety of structures to accommodate different needs.

From simple to complex: the evolution of bearings

Early forms of linear motion bearings consisted of a row of wooden rods placed beneath a row of pry bars. The working principle of modern linear motion bearings is similar, though sometimes balls are used instead of rollers. The simplest rotating bearing is the sleeve bearing, which is simply a sleeve sandwiched between the wheel and the axle. This design was later replaced by rolling bearings, which use numerous cylindrical rollers instead of the original sleeve, with each rolling element functioning like an individual wheel.

Lifespan differences

Although bearings appear simple, their service life varies depending on factors such as manufacturing precision and material uniformity. Even bearings made from the same material and of the same size within the same batch may have significantly different service lives when used under the same working conditions.

Post time: May-29-2025