Maximizing Efficiency: The Unique Advantages of Cam Follower Needle Roller Bearings in Modern Manufacturing

Table of Contents

- Advantages of Cam Follower Needle Roller Bearings in Manufacturing Applications

- Key Features that Enhance Efficiency in Modern Machinery

- Comparative Analysis: Cam Follower Bearings vs. Traditional Bearings

- Best Practices for Implementing Needle Roller Bearings in Production Lines

- Maintenance Tips for Maximizing the Lifespan of Cam Follower Bearings

- Enhancing Machinery Efficiency with HCSZ High Performance Low Noise Roller Needle Bearings: Insights from Industry Performance Reports

- FAQS

- Conclusion

- Related Posts

These days, with how quickly modern manufacturing is moving and changing, there's never been a better time to focus on reliable, efficient components. I recently read a report that estimates the global bearing market will hit around 78 billion USD by 2026. That growth is mainly fueled by new tech advances and more automation happening all over the place—think automotive projects, mining equipment, and more. One standout in this field is the Cam Follower Needle Roller Bearing. It’s pretty popular because it’s compact yet can handle really high loads, making it a go-to choice for all sorts of heavy-duty applications like cars and mining machinery. And speaking of companies leading the charge, Shandong Hangshuo Bearing Co., Ltd. has been around since 2015 and is really pushing the boundaries in this space. They focus on creating cutting-edge bearing solutions, offering everything from automotive to mining and farming machinery bearings. Basically, they’re all about helping industries run smoother and perform better—that’s the goal, at least.

Advantages of Cam Follower Needle Roller Bearings in Manufacturing Applications

You know, in today's manufacturing world, Cam Follower Needle Roller Bearings are really starting to make a difference when it comes to boosting efficiency across different applications. They're especially great for indexing machines and automated assembly lines where precision and reliability aren’t just nice to have—they're essential. Industry folks have been saying that the global market for these needle roller bearings is going to keep growing steadily, mainly because automation tech keeps advancing. These cam-driven systems pack a punch with their compact size, lower friction, and their ability to handle heavier loads, which makes them perfect for applications that need tough, long-lasting parts.

What's also cool about Cam Follower Needle Roller Bearings is how smooth they make the movement, especially in high-speed setups. As automation becomes a bigger part of manufacturing, these bearings are just more valuable because they help speed up cycles and cut down on maintenance costs. Companies are really looking for ways to be more efficient and deliver better quality, so they’re investing in components like these to hit their production targets. Shandong Hangshuo Bearing Co., Ltd., with its focus on innovative bearing tech, is pretty well-placed to meet the changing needs of industries—from automotive to mining machinery—and all that really helps push manufacturing forward.

Key Features that Enhance Efficiency in Modern Machinery

You know, in today's manufacturing world, the way we improve machinery efficiency really benefits from using cam follower needle roller bearings. They're quite the game-changer compared to regular bearings. What's pretty cool is that these bearings can handle heavy radial loads yet keep friction low — which is super important when machines are running at high speeds. I recently came across a report from the Bearing Specialists Association that said switching to needle roller bearings can cut down energy use by as much as 30%. That’s a lot of saved bucks for manufacturers out there.

And here's another thing I find interesting — their compact design. These bearings take up much less space, so you can squeeze them into tighter spots without losing performance. That’s a real plus, especially in fields like automotive and aerospace, where making lightweight, space-efficient parts is a major deal. Some research even shows that using advanced bearing tech like needle rollers can bump up overall machinery efficiency by about 15%. All in all, they’re pretty essential in keeping modern manufacturing running smoothly and efficiently.

Comparative Analysis: Cam Follower Bearings vs. Traditional Bearings

When it comes to modern manufacturing, picking the right kind of bearings can really make a big difference in how smoothly things run. Cam follower needle roller bearings, for example, have some pretty noticeable perks compared to your basic bearings. Unlike the usual ball or roller types, cam followers are built specifically for heavy loads and can handle shocks way better. Plus, their unique design means they can be more compact, saving space and reducing weight in your machinery. That kinda flexibility can really give your designs an edge and boost performance, especially in environments that are constantly moving and changing.

Oh, and here's a little tip—when you're choosing bearings for your setup, think about the specific loads your machine will face. Cam follower needle roller bearings are especially great when you're working in tight spaces or dealing with high push and pull forces from all directions.

They’re not just tough, either. They tend to have lower friction compared to traditional bearings, which means your machinery runs more smoothly and uses less energy. That can actually save you some bucks on power costs and is also better for the environment. Plus, since these bearings are super durable, you'll probably need to replace them less often, which just adds to their value.

Another tip—if you're unsure about which bearing to go with, it’s worth chatting with a bearing expert. Picking the right type can really save you some serious money in the long run.

Best Practices for Implementing Needle Roller Bearings in Production Lines

In today’s fast-moving world of manufacturing, bringing needle roller cam follower bearings into play is a smart move if you’re aiming for top efficiency. I read in the International Journal of Advanced Manufacturing Technology that companies using these bearings in their production lines have seen about a 25% boost in how smooth and efficient things run. The cool thing is, they’re great at handling heavy radial loads and fit into tight spaces, which means machines can be lighter and more streamlined — pretty nifty, right?

Now, if you’re thinking about making the switch, a couple of tips can go a long way. First off, it's super important to get those bearings aligned just right during installation — slacking on that can lead to early wear or even failures. And don’t forget, regular maintenance and lubrication are key. A study from the Society of Manufacturing Engineers suggests that keeping up with proper care can actually extend the life of these bearings by up to 40%. Plus, when operators understand how to leverage the benefits and apply these bearings correctly, the machinery downtime drops significantly. All in all, sticking to these simple practices means manufacturers can unlock the full potential of cam follower needle roller bearings, giving themselves a serious edge in the industry.

Maintenance Tips for Maximizing the Lifespan of Cam Follower Bearings

When it comes to taking care of cam follower needle roller bearings, really understanding their unique designs and how they perform is pretty important if you want them to last as long as possible. Regular maintenance isn't just a chore—it can actually make a big difference, especially in today’s manufacturing world where precision and durability are everything. Some industry reports even suggest that with proper lubrication and alignment, you can boost the service life of these bearings by up to 50%. So, sticking to routine checks and re-lubricating on schedule helps prevent issues caused by dirt, misalignment, or wear-and-tear, which means smoother operation and less downtime overall.

And don’t overlook the power of using high-quality lubricants made specifically for cam follower bearings. It’s a small change that can really pay off—reducing friction and overheating, which leads to longer-lasting performance and lower maintenance costs down the line. Plus, training your maintenance team on the best practices for installing and adjusting these bearings can make a difference too. All in all, by paying attention to these simple tips, manufacturers can unlock the full potential of cam follower needle roller bearings, keeping things running smoothly and reliably in their production lines.

Enhancing Machinery Efficiency with HCSZ High Performance Low Noise Roller Needle Bearings: Insights from Industry Performance Reports

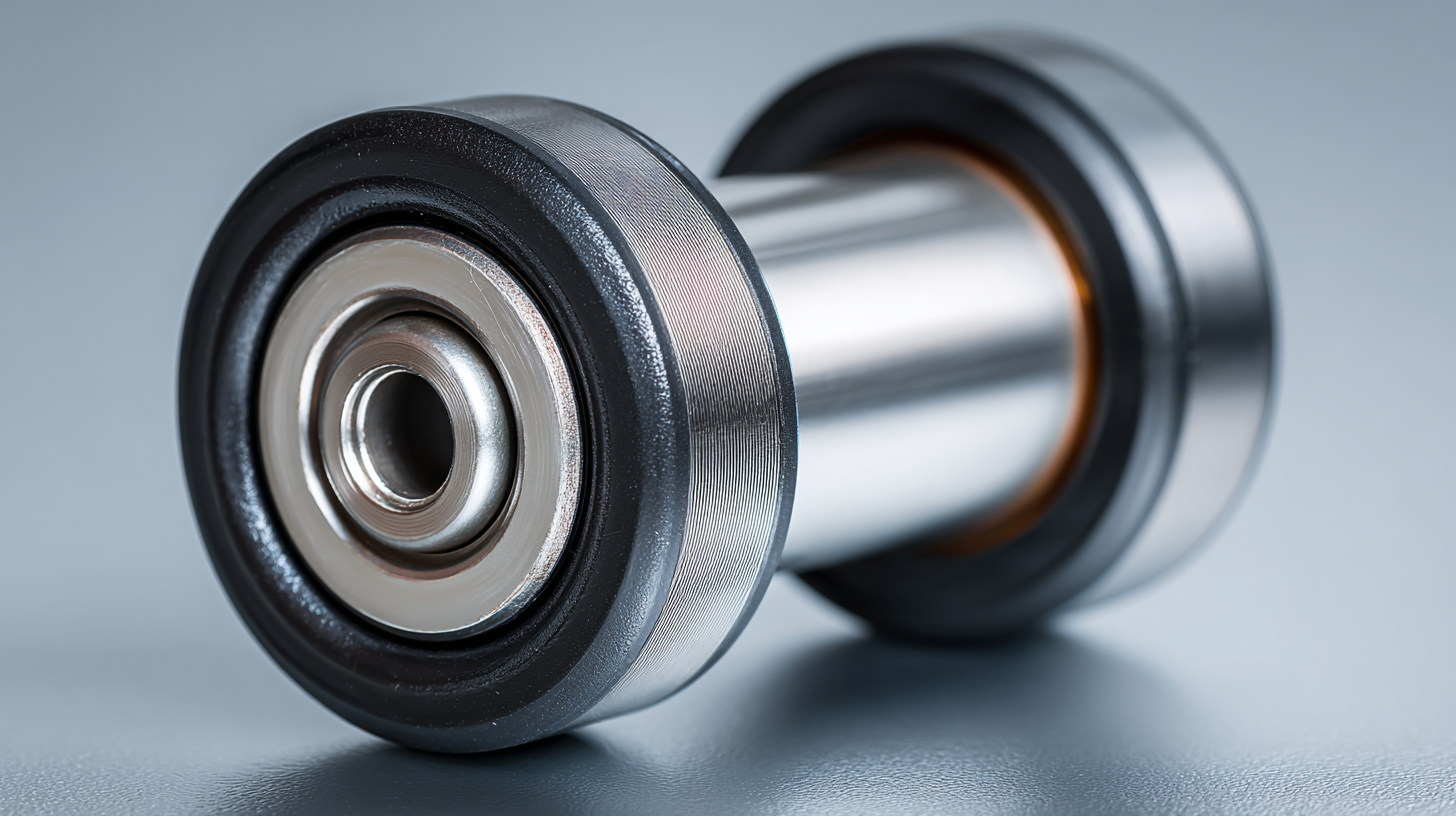

In the quest for enhanced machinery efficiency, the choice of bearings plays a critical role. The HCSZ High Performance Low Noise Roller Needle Bearings stand out in this regard, as they combine advanced engineering with remarkable performance capabilities. These needle bearings feature cylindrical rollers that are not only thin but also elongated, providing a unique design that maximizes load-carrying capacity without compromising on space. Industries seeking to minimize friction and noise in their operations can significantly benefit from the incorporation of these bearings into their machinery.

Performance reports across various sectors have consistently highlighted the advantages of using HCSZ needle roller bearings. These bearings excel in high-load applications, while their low-profile design allows for efficient compactness, making them ideal for modern machinery that requires both strength and agility. Furthermore, the innovative technology behind these bearings contributes to reduced vibration and noise levels, enhancing overall operational comfort and longevity. By upgrading to HCSZ High Performance Low Noise Roller Needle Bearings, businesses can achieve higher productivity levels and maintain a competitive edge in today's fast-paced industrial landscape.

FAQS

: Cam Follower Needle Roller Bearings are specialized bearings designed to enhance efficiency and reliability in various manufacturing applications, particularly in indexing machines and automated assembly systems.

They offer smoother motion, reliability in high-speed applications, reduced maintenance costs, and improved cycle times, making them ideal for modern manufacturing processes.

The use of needle roller bearings can lead to a reduction in energy consumption by up to 30%, resulting in significant cost savings for manufacturers.

Their compact design allows for efficient space utilization in machinery, which is essential in industries like automotive and aerospace where lightweight components are in demand.

Research indicates that the adoption of Cam Follower Needle Roller Bearings can contribute to a 15% increase in overall machinery efficiency.

Best practices include ensuring precise alignment during installation, regular maintenance and lubrication, and training operators on the advantages and applications of these bearings.

Proper maintenance can extend the lifecycle of needle roller bearings by up to 40%, reducing the risk of premature wear and failure.

Companies that have integrated needle roller bearings into their production lines have reported a 25% increase in operational efficiency.

These bearings are useful in various sectors, including automotive, aerospace, and mining machinery, where durability and performance are critical.

By enhancing machinery efficiency and operational effectiveness through their unique advantages, these bearings help manufacturers improve their competitive edge in the industry.

Conclusion

You know, in today’s manufacturing world, keeping things running smoothly and efficiently is more important than ever. That’s where the Cam Follower Needle Roller Bearing really shines. These little guys pack quite a punch—they help reduce friction, save space with their compact design, and can handle heavy loads better than many traditional options. Not only do they boost machinery performance, but they also help keep production lines running more productively overall. When you compare Cam Follower Bearings to the older, more classic types, it’s pretty obvious they offer way better performance across different industries. And for companies like ours, Shandong Hangshuo Bearing Co., Ltd., they’re definitely a game-changer.

To get the most out of these bearings, it’s a good idea to follow some best practices—things like regular maintenance can really make a difference. Keeping them well-maintained means your machinery stays in top shape longer and operates efficiently. Since we started back in 2015, we’ve been dedicated to providing high-quality bearing solutions that cater to a wide range of sectors—whether it’s automotive, mining, engineering, textiles, or agriculture. We’re all about helping our customers keep their machines running smoothly, no matter what industry they’re in.

Blog Tags: